SPARTUS Filtration & Ventilation – effective air protection in welding processes

SPARTUS filtration and ventilation systems are professional fume extraction solutions that ensure a clean and safe working environment. The range includes mobile filters, extraction arms, downdraft tables and complete ventilation installations for workshops, production halls and dedicated workstations. SPARTUS devices comply with welding fume emission standards, effectively removing dust, gases and particles generated during welding, cutting and grinding.

Aero Clean extractors and extraction arms – flexible solutions for welding stations

The Aero Clean system and SPARTUS extraction arms are ideal solutions for point-based welding stations. Precise arm positioning enables capturing fumes directly at the source, minimizing operator exposure. These compact and easy-to-install solutions are indispensable in small and medium workshops.

Mobile fume filters – Air Master, ProVent and ClearStream for demanding users

SPARTUS mobile filters – Air Master, ProVent and ClearStream – are high-performance filtration units designed for areas where fixed installations cannot be installed. Multi-stage filters effectively capture welding fumes, dust and aerosols, ensuring clean air even during intensive processes. The units are equipped with automatic filter cleaning systems, extending filter life and reducing operating costs.

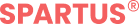

Downdraft tables, fans and Vortex ducts – a complete filtration system for your facility

SPARTUS downdraft worktables combine efficient fume extraction with the functionality of a grinding or welding table, ensuring high workplace safety. The offer also includes industrial fans and the modular Vortex ducting system, allowing the construction of a complete extraction installation tailored to a specific workshop or production hall.

Frequently

asked questions

Which welding fume extractor should I choose for a workshop?

For single workstations, Aero Clean extraction arms or Air Master mobile filters work best.

What is the difference between the Air Master, ProVent and ClearStream mobile filters?

Air Master is a compact model for mobile work areas, ProVent offers higher filtration efficiency and automatic filter cleaning, while ClearStream is designed for heavy-duty applications and continuous operation.

How often do the filters need to be replaced in ProVent and ClearStream units?

In systems with automatic cleaning, filter replacement is much less frequent — usually every 12–24 months, depending on workload. Without cleaning, the filter sets wear out significantly faster.

What is the difference between HEPA, cassette and cartridge filters in welding ventilation systems?

-

HEPA filters – capture the finest particles (99.95–99.995%); ideal for stainless steel and aluminium; used as the final filtration stage.

-

Cassette filters – large filtration surface, resistant to high dust loads, often equipped with automatic cleaning; best for intensive MIG/MAG welding and cutting.

-

Cartridge filters – compact, cylindrical, perfect for mobile units; good efficiency for applications with lower fume emissions.