Boost your work efficiency with modern solutions!

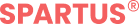

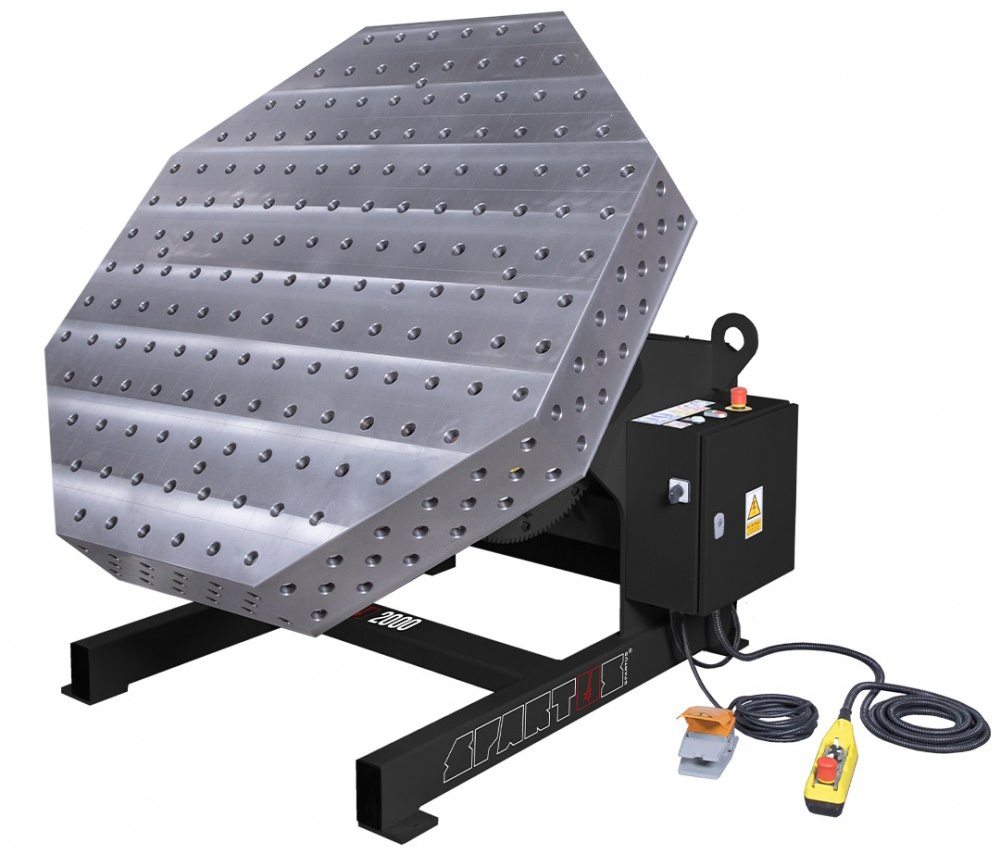

SPARTUS Ferros welding tables integrated with a welding positioner offer a solution that significantly enhances ergonomics and efficiency when welding components of various shapes and sizes. The ability to rotate and position the workpiece at the optimal angle gives the operator full control over the weld position, resulting in higher quality and repeatability of joints. The table’s robust construction and stable mounting to the positioner ensure work safety and user comfort, even during complex technological operations.

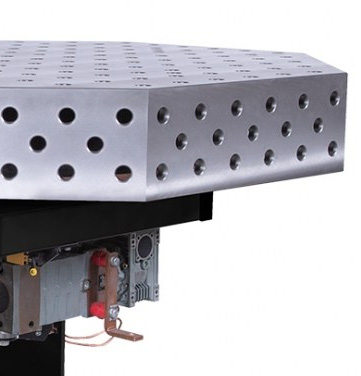

Cast iron welding table top – strength and stability

The SPARTUS FERROS welding table top is made of EN-GJL-300 cast iron – a material with high strength and exceptional wear resistance. Thanks to this type of cast iron, the welding table maintains dimensional stability and resistance to mechanical damage even during intensive use. The structure of the tabletop provides not only durability but also excellent vibration-damping properties, which are crucial for welding precision.

25 mm dla maksymalnej trwałości

The 25 mm thick SPARTUS FERROS welding table top provides exceptional durability and resistance to mechanical damage. Such a robust construction ensures stability even when working with heavy components and under intense load, making the table highly reliable for everyday use. The thick tabletop also means longer service life and increased safety during welding.

precyzja w każdym detalu

The SPARTUS FERROS welding table top is equipped with a printed millimeter scale, which greatly facilitates precise positioning of workpieces. Thanks to the clear markings, the user can quickly and accurately set components, resulting in higher efficiency and repeatability of operations. This practical feature supports accuracy at every stage of the welding process.

D28 System – compatibility and precise clamping

SPARTUS FERROS welding tables use the D28 hole system — a grid of 28 mm diameter holes drilled and milled with the highest precision. This design ensures full compatibility with D28 system accessories and allows for quick and accurate clamping of components in any configuration. It’s a reliable solution for professionals who value flexibility and precision in their daily workshop operations.

Various tabletop sizes – adapt the table to your needs

SPARTUS FERROS welding tables available in the welding positioner version come in an octagonal shape and are offered in two sizes: 1200×1200 mm and 1400×1400 mm. This design provides excellent access to the workpiece from all sides, making it easier to perform precise welds without frequently repositioning the component. Such tables are an ideal solution for workstations that require high flexibility and comfort when welding parts with more complex geometries.

SPARTUS welding positioner – full control over the position of the welded component

Integrating the SPARTUS Ferros table with a welding positioner allows precise adjustment of the working position to the user’s individual needs. The rotating worktop with smooth speed control can rotate in both directions, and the device’s design enables tilting of the main frame up to 140° relative to the horizontal plane. When the table is mounted, the maximum tilt angle is 90°, which is more than sufficient for comfortable and ergonomic access to any weld. The self-locking drive allows the table to stop at any position, while intuitive control is provided via a handheld control panel and a foot switch connected by a separate cable.

Key advantages:

– rotating worktop with bidirectional operation

– adjustable table tilt angle

– smooth rotation speed control

– convenient and intuitive operation

| Welding positioner | SPARTUS 1000 | SPARTUS 1500 | SPARTUS 2000 | SPARTUS 5000 |

| Table height | 1090mm | 1090mm | 1090mm | 1220mm |

| Positioner load capacity | 1000kg | 1500kg | 2000kg | 5000kg |

Specyfikacja techniczna

| Size of the work surface | 1200x1200x200mm | 1400x1400x200mm |

| Made | casted | casted |

| Material | EN-GJL-300 cast iron acc. to EN 1561 | EN-GJL-300 cast iron acc. to EN 1561 |

| Table top thickness | 25mm | 25mm |

| Table horizontal precision | 0.1/1000mm | 0.1/1000mm |

| Table vertical precision | 0.1/200mm | 0.1/200mm |

| Standard | D28 (drilled and milled holes 28mm diameter) | D28 (drilled and milled holes 28mm diameter) |

| Carrying capacity | depending on the positioner used | depending on the positioner used |

| Supporting structure | positioner | positioner |

| Table top weight | 480kg | 650kg |