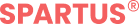

ENSURE LASTING SUPPORT WITH MAXIMUS TABLES!

The SPARTUS Maximus welding table is designed for the most demanding applications, where maximum stability, durability, and precision in positioning components are essential. Made from the highest-quality materials, it offers unlimited possibilities for configuring the workstation. Thanks to its solid construction and excellent resistance to deformation, the SPARTUS Maximus table ensures reliability even under intensive use, enabling perfect welding results every single day.

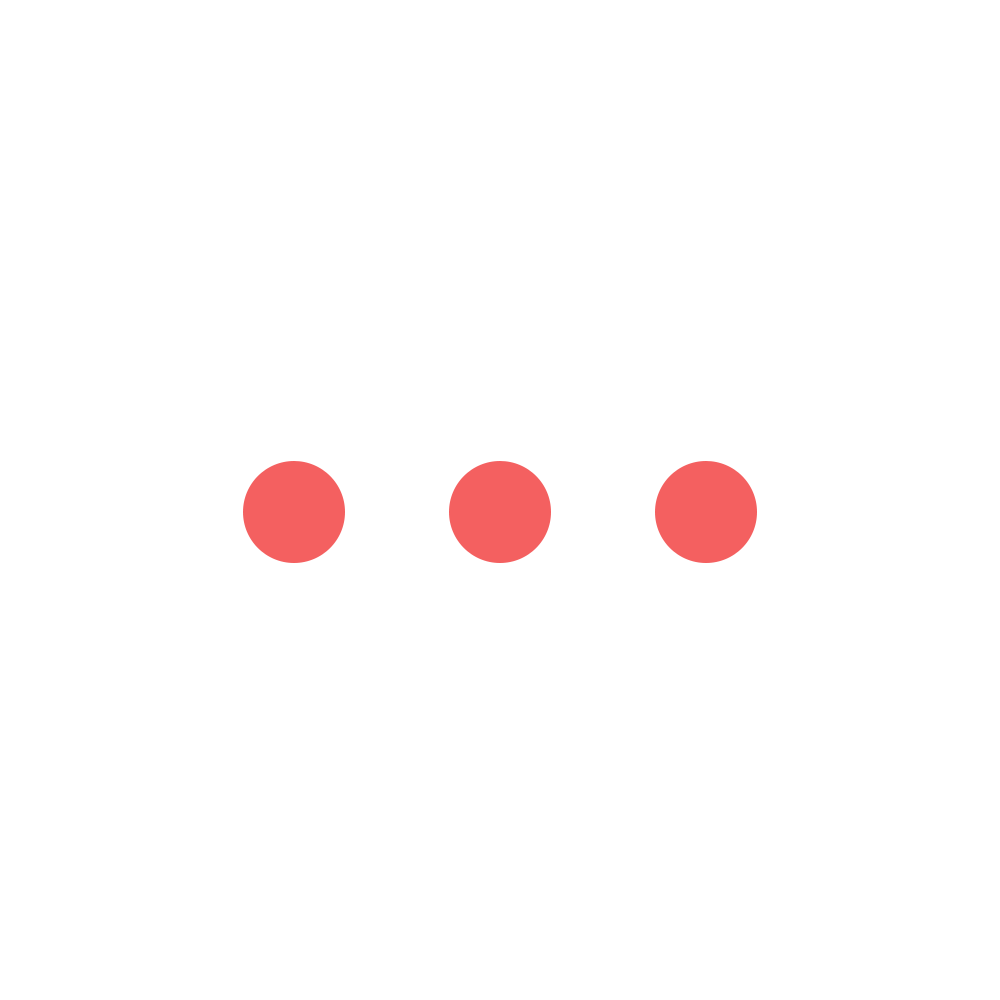

S355J2+N Steel with Nitrided Surface – Maximum Protection and Durability

SPARTUS Maximus is made of S355J2+N structural steel, which provides exceptional mechanical strength and resistance to impacts and deformation. Additionally, the worktop has undergone a plasma nitriding process, which significantly increases its resistance to corrosion, wear, and welding spatter. As a result, the table maintains its properties and aesthetic appearance for a long time, even under intensive use in demanding industrial environments.

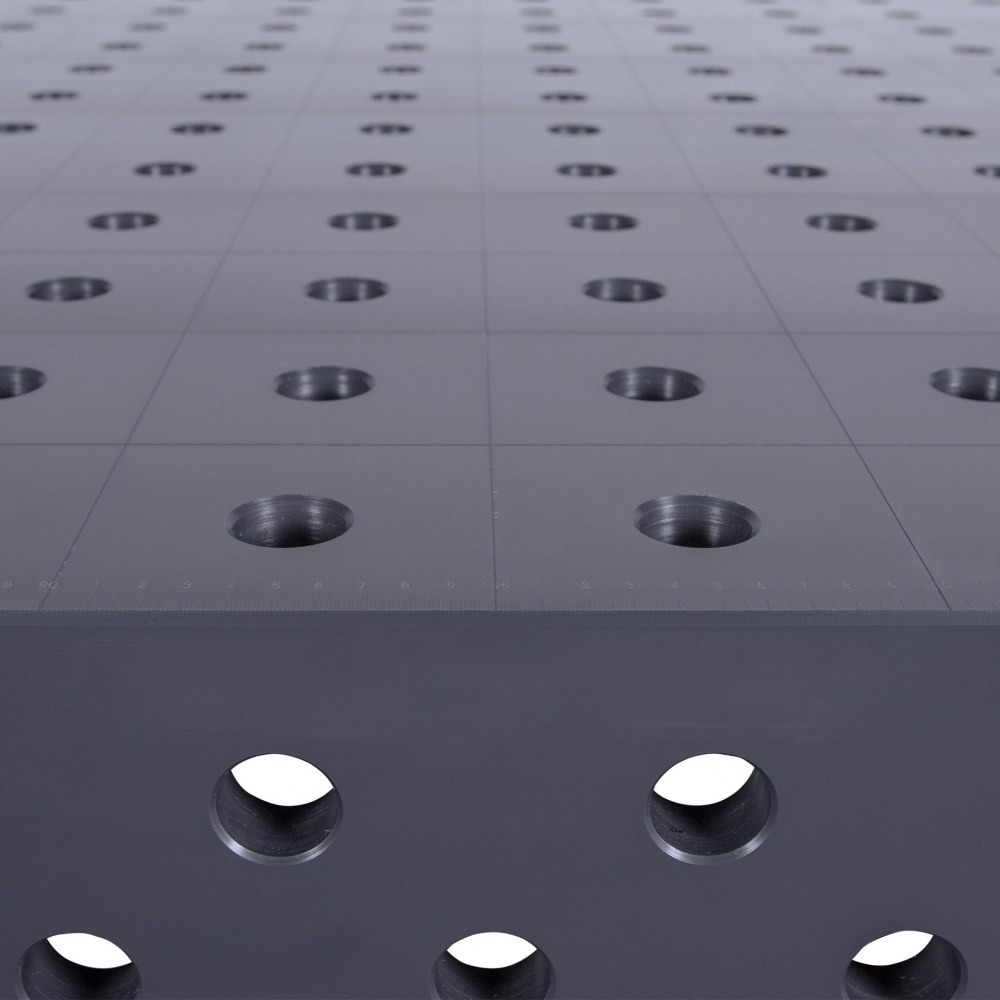

25 mm for Maximum Durability

The 25 mm thick worktop of the SPARTUS MAXIMUS welding table provides exceptional durability and resistance to mechanical damage. Such a solid construction ensures stability even when working with heavy components and under intense loads, resulting in reliable performance in everyday use. The thick worktop also means greater table longevity and enhanced safety during welding.

Precision in Every Detail

The worktop of the SPARTUS MAXIMUS welding table is equipped with a millimeter scale that significantly facilitates precise positioning of workpieces. Thanks to the clear markings, the user can quickly and accurately set up components, improving both efficiency and repeatability of tasks. This practical feature supports accuracy at every stage of the fabrication process.

Flexibility and Workstation Expansion

The use of 3D side panels in SPARTUS MAXIMUS welding tables allows for easy expansion of the working surface and the connection of multiple tabletops into one cohesive system. This enables the user to adapt the workstation to the size and nature of the workpieces, enhancing both functionality and comfort. It’s an ideal solution for workshops that value modularity and expandability.

D28 System – Compatibility and Mounting Precision

SPARTUS HERMES welding tables use the D28 hole system — a grid of 28 mm diameter holes, drilled and milled with the highest precision. This design ensures full compatibility with D28 system accessories and allows for quick and accurate clamping of components in any configuration. It’s a reliable solution for those who value flexibility and precision in everyday workshop operations.

Flexible Base Configuration

SPARTUS MAXIMUS welding tables are available with two leg variants: with a fixed foot or with a caster wheel. The fixed-foot version provides maximum stability and a secure base during intensive work, while the caster-wheel version allows for easy movement of the table within the workshop. Both options affect the final height of the table, so selecting the appropriate variant allows you to tailor the workstation to your individual needs and working conditions.

| Table Height | 450mm | 600mm | 700mm | 800mm | 870mm |

| Leg Height with Foot | 200mm | 350mm | 450mm | 550mm | 620mm |

| Table Height | 520mm | 670mm | 770mm | 870mm | 940mm |

| Leg Height with Caster Wheel | 200mm | 350mm | 450mm | 550mm | 620mm |

Various Worktop Sizes – Customize the Table to Your Needs

SPARTUS MAXIMUS welding tables are available in several practical size variants, allowing for a perfect fit to the specific requirements and dimensions of the workstation. The available worktop sizes are: 1500×1000 mm, 2000×1000 mm, 2400×1200 mm, and 3000×1500 mm. This variety enables optimal use of workshop space and ensures comfortable work regardless of the size of the welded components.

Technical Specifications

| Size of the work surface | 1500x1000x200mm | 2000x1000x200mm | 2400x1200x200mm | 3000x1500x200mm |

| Made | welded with protective coating (Nitrided) | welded with protective coating (Nitrided) | welded with protective coating (Nitrided) | welded with protective coating (Nitrided) |

| Material | S355J2+N steel acc. to EN 10025-2 | S355J2+N steel acc. to EN 10025-2 | S355J2+N steel acc. to EN 10025-2 | S355J2+N steel acc. to EN 10025-2 |

| Table top thickness | 25mm | 25mm | 25mm | 25mm |

| Table horizontal precision | 0.3/1000mm | 0.3/1000mm | 0.3/1000mm | 0.3/1000mm |

| Table vertical precision | 0.3/200mm | 0.3/200mm | 0.3/200mm | 0.3/200mm |

| Standard | D28 (drilled and milled holes 28mm diameter) | D28 (drilled and milled holes 28mm diameter) | D28 (drilled and milled holes 28mm diameter) | D28 (drilled and milled holes 28mm diameter) |

| Carrying capacity | 2000kg/leg | 2000kg/leg | 2000kg/leg | 2000kg/leg |

| Number of legs | 4pcs | 4pcs | 6pcs | 6pcs |

| Table top weight | 535kg | 720kg | 960kg | 1500kg |